Plastic components are used in virtually every type of industry. But requirements for processes, production, materials and logistics may vary from one application to another. We understand these differences.

In electronics, what matters is consistently high quality. Special materials, for example antistatic, are often needed, and the combination of plastic and metal parts also entails special challenges. We know this and provide industry-specific solutions.

The Repo Service Profile

Products: parts for electronics, sensor and home automation components.

High quality requirements, product durability, and demand-driven delivery, even of small batches, make all the difference: our services fit the needs of companies in the field of intralogistics like a glove.

The Repo Service Profile

Products: parts for automation components, drive and roller technology

The car industry demands the highest precision, perfect customer service, consistently high product quality and absolutely reliable delivery times. With our services, we can accurately meet all industry requirements.

The Repo Service Profile

Products: housings for pressure sensors or electronic connections.

Design focus and variety of models and colors, as well as stringent material requirements, require flexibility and industry experience. We offer customized solutions for the production of kitchenware that meet quality and sustainability standards.

The Repo Service Profile

Products: cutlery for home, hotel and professional kitchens, components for home appliances and food applications.

Attention to detail and in-depth expertise in sustainable materials and bioplastics are essential today in the world of design and furniture: we provide what it takes to support designers to create innovative and functional design products.

The Repo Service Profile

Products: design accessories, semi-finished products and components for furniture and wiring systems.

Cost-optimized tools and processes, expert support in the development of semi-finished products and components, and material selection: we provide practice-driven solutions to technical problems in construction.

The Repo Service Profile

Products: semi-finished products, disposable components for building sites and construction, as well as components for shutters or fastening systems.

Individual support at all stages of product development, from co-design to prototyping, from mold making to production – we have what it takes to turn ideas into products.

The Repo Service Profile

Products: ideas that become reality.

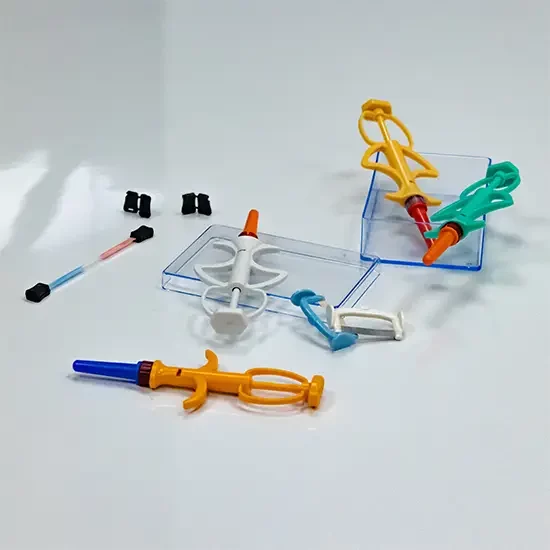

In the healthcare sector, accurate knowledge of all legal requirements is essential. . With our solutions, we offer what it takes to produce standards-compliant medical devices and appliances.

The Repo Service Profile

Products: i.e. dental device components.